RPA in Manufacturing

Robotic process automation (RPA) is a real game-changer in the manufacturing industry, even more so than in other branches of the business. For companies with multiple branches of factories and offices, keeping and managing the data in the system can be quite overwhelming. Deploying RPA services in this area can greatly help with monitoring, accessing and updating any changes within the web-connected systems. And by doing so, reduce the communication time between one branch and another.

Continuous pressure from the global market and the need to reduce the costs makes the companies from the manufacturing industry look out for new and innovative solutions. RPA is such a solution. And what is more, robotic process automation introduces transparency, agility and enhance the customer experience by supporting the entire supply chain and warehouse management.

For manufacturing companies that are looking for an efficient (and reasonably cheap) solution to unlock their full potential, increase productivity and improve management and administration, it might be worth implementing RPA in every functional area.

But what exactly is robotic process automation (RPA)? To put it simply, this is software that can be fully integrated with your business processes. What for? To automate repetitive, mundane activities, minimize human error risk and also maximize productivity. It is worth mentioning that the automation happens end-to-end so you do not have to worry about supervising the processes or operations once you have the RPA bots.

If you are a manufacturer of parts or machinery, think of all the processes that you have and that could be automated. Those tasks could be:

- Payment/ refund processing

- Customers import processing

- Generation of finance contracts

- Reconciling expenditures

Now let’s imagine you get the above automated. By looking at the examples, it might save you $6 million a year of savings and reduce the working hours each month by 2 500. Mind you that the tasks automated with RPS can run 24/7. Also unattended – without human supervision. Yes, the future is here.

Benefits of Robotic Process Automation in manufacturing

Robotic Process Automation bots can help in many ways in manufacturing industries. The RPA implementation helps make the supply chain stronger and replace routine activities around quoting and invoicing, accounts receivable and payable or general ledger operations.

Robotic process automation (RPA) in manufacturing also enables the companies to tailor billing and production objectives with no human errors and guidance provided for employees. The implementation of RPA services also simplifies the process of handling compliance issues by maintaining a track of all activities and assurance of data processing according to regulatory and business requirements for a given business.

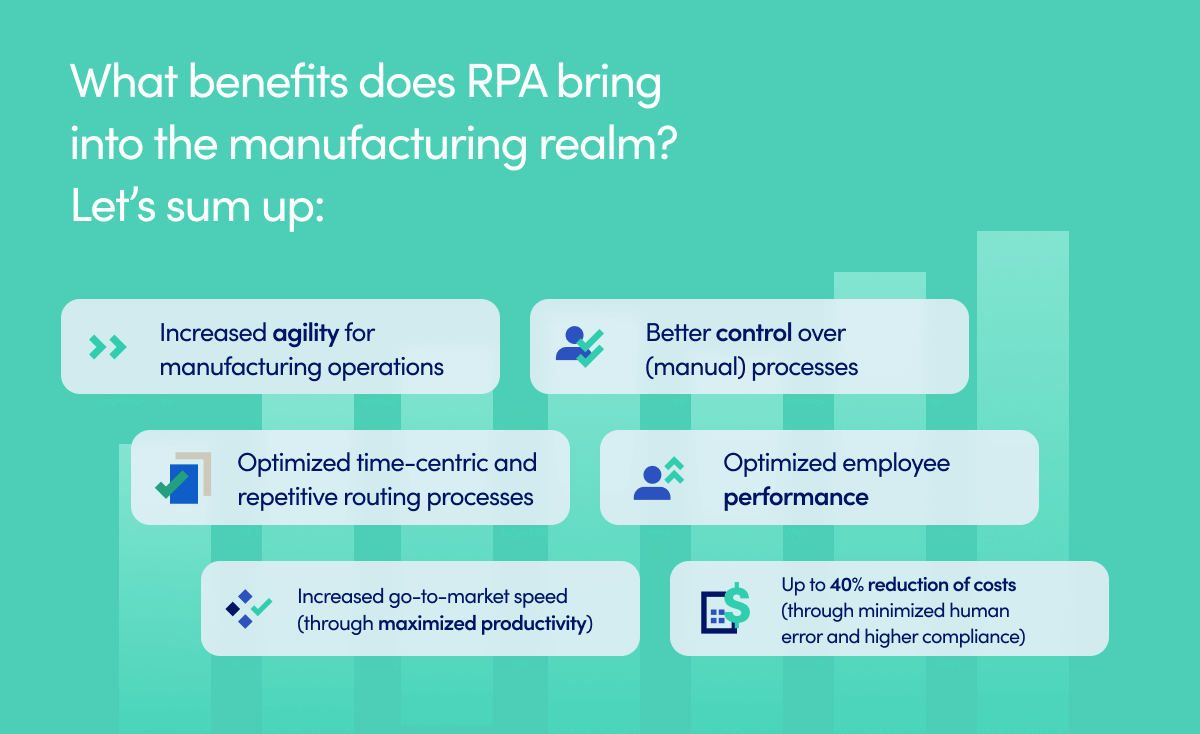

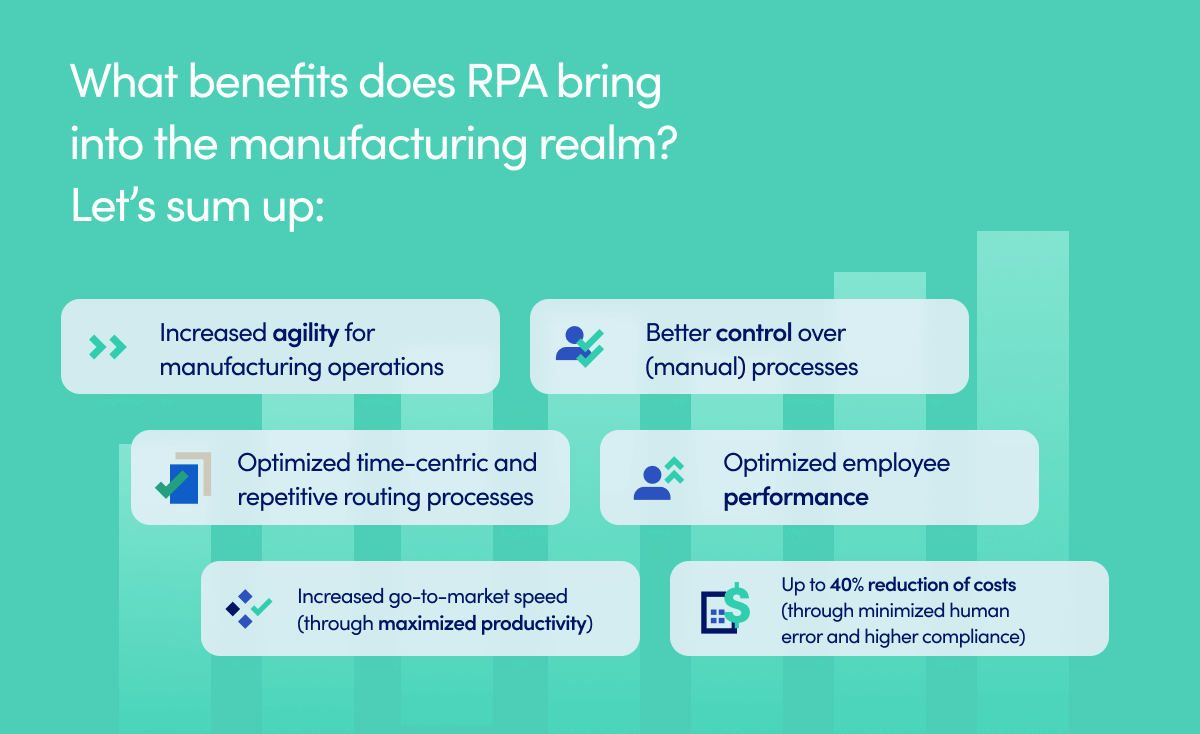

What benefits does RPA bring into the manufacturing realm? Let’s sum up:

- Increased agility for manufacturing operations

- Better control over (manual) processes

- Optimized time-centric and repetitive routing processes

- Optimized employee performance

- Increased go-to-market speed (through maximized productivity)

- Up to 40% reduction of costs (through minimized human error and higher compliance)

The advantages of robotic process automation in manufacturing when combined with AI are endless. It allows for:

-

- Predictive maintenance: as machine downtime is very costly and risky to the business, AI combined with RPA should be used to predict machine downtime and maintenance times so that all physical production processes run uninterrupted.

-

- Price forecasting: RPA and AI-assisted automation can run calculations based on historic prices of materials and thus, predict future prices and update the budgets. You can also automate even more complex pricing for budgetary calculations with help offered by robotic process automation bots.

-

- Shipping automation: controlling the shipping processes is burdensome and meticulous. With RPA and AI-based intelligence, you can make these processes faster and smoother through instant data recognition, help in sorting packages and making complicated shipping reports and calculations.

-

- Extendable manufacturing capabilities: machine memory and fast processors or RPA bots guarantee that umpteen tasks are completed in a fraction of time. What this impacts is also the extension of the manufacturing ERP system with any number of necessary manufacturing functionalities.

-

- Production customization: apart from manufacturing capabilities, RPA services can be deployed for a lot of other routing and rules-based tasks. The activities can be performed by RPA bots in parallel and much faster that any human is capable of. You can, for example, integrate RPA programmed for inventory requisitions classification with your ERP to procure real-time inventory levels.

- Manufacturing agility: the great advantage of RPA over other types of automation is that it us extremely easy to set up and deploy. Low-code solutions (for example Microsoft Power Platform) do not require the assistance of any IT resources. Even with little system or technical knowledge, business operations executives can improve the system’s performance. Hence, the manufacturing process is more agile and also responsive to the changing business and market landscape.

RPA examples and use cases in the manufacturing industry

In the previous section, you saw what benefits robotic process automation can trigger for manufacturers. Overall, it eliminates up to 65% of manual workload and the processes can be done by both with no human intervention (of course except any unexpected events).

Now let’s take a closer look at what areas RPA can improve when talking about the manufacturing industry:

Purchase Order Creation

Manual handling of purchase orders – mainly their creation – can be very challenging for companies, particularly those with multiple product categories. With the helping hand of RPA bots, the entire PO creation process can be automated. This guarantees both 100% accuracy but also speeds up the whole process. Robotic process automation in manufacturing can extract data from independent system, execute approval path and process the PO creation request.

Inventory Management

The automation of inventory monitoring, stock-level notifications and product reordering processes can be enhanced with the implementation of robotic process automation. Bots allow you to create detailed audit trails and use dashboards and reports with data in real-time that can be used as insights for process optimization and improvement of the supply chain.

Vendor Communication

On a daily basis, manufacturing requires communication between the onsite workforce, vendors and the customers. This involves a lot of manual steps but… does not have to. Robotic process automation can take over the whole communication process. Instead of answering the inquiry concerning the goods shipped through going to the ERP system, looking for data and sending the update to the customer, the workers can easily delegate those tasks to RPA bots. They are able to open the mail, read its contents, download all attachments, log into the ERP portal, check the shipment status and send a reply automatically. Ad infinitum.

Bill of Materials

One of the most important production documents – Bill of Materials (BOM) – includes all the necessary data for the new product creation: a long list of raw materials, components, sub-components and other products. All employees in the manufacturing industry refer to the document for detailed info on where, when, what to purchase and how to do this. This means that if any error happens in a BOM, it results in gigantic losses for the business. With RPA, you make sure that it doesn’t happen. You get better data accuracy and also the product creation is always completed on time.

Administration and reporting

Although not an area that it typical for manufacturing, still running a (successful) manufacturing business requires the admin department, too. With the implementation of robotic process automation services, the company can get all the reports of their production and related workload in their business much faster, the data is always accurate and does not require long data entry working hours. As a result, manufacturers can take decisions more quickly, analyze data in real time and run their business more effectively – by delegating repetitive and monotonous workload that is error-prone to RPA bots.

Customer Support and Service Desk

Robotic process automation has a lot to offer for customer service within the manufacturing industry. It can be extremely helpful in the front office for enhanced communication with the customers. Employees with bots do not have to navigate multiple systems anymore to access data. All the multiple stored data can be accessed with RPA at one place. Robotic process automation bots can also be used to set reminders for when to follow up with the given customer, maintain the contact schedule and trigger employees whenever a complaint is filed.

Logistics data

Integrating the transport management system within the logistic department with RPA increases the effectiveness of the transportation of manufactured goods. Apart from enhanced service, the companies reduce the risk of human error. On top of that, with multiple carriers and insurances, RPA can generate the reports that help with choosing the service with the best cost, transit time, etc. You also can benefit from real time freight option by including the RPA in the transport management system.

Data migration

A standard part of the manufacturing life is moving data from old to newly replaced systems. As costly as the process is, it has to be done. Robotic process automation can be a great helping hand with production data migration. Whenever a company acquires new business, they can reduce the periods and costs with proper planning and execution of the RPA for keeping the book of business with the policies.

Learn more about

Microsoft Dynamics 365 for Manufacturing.