Global need for digital manufacturing

- According to the report from 2021 (Gartner), 50% of factory work is to be done remotely. The post-Covid era has clearly put new demands on skills, technology and tools of manufacturing leaders in the area of innovation. They should:

Marry innovation and production: manufacturers, especially lean workforces, need to be ready to align their production systems with innovative operations and new metrics that would integrate the way modern factories are managed

- Bring transformation to the shop floor: digitization and shedding manual tasks will transform production workplaces through developing new capabilities

- Create demand for continuous improvement: successful innovation should be a collective result of project leads sharing their experiences with stakeholders in order to attract investors and stay in the game

Why you should use Dynamics 365 for your manufacturing business

Manufacturing does not have to be a heavy-processed industry any more. Cloud computing and modern ERP systems empower manufacturers to optimize their processes and excel at what they do.

What this means is that optimization of any areas is feasible only through the adoption of new technology. Solutions such as Microsoft Dynamics 365 SCM allow the manufacturing companies to achieve the goals that will allow them to develop their supply chain and prevent any disruptions. Let’s have a look at how manufacturers can rise above their industry challenges and stay competitive.

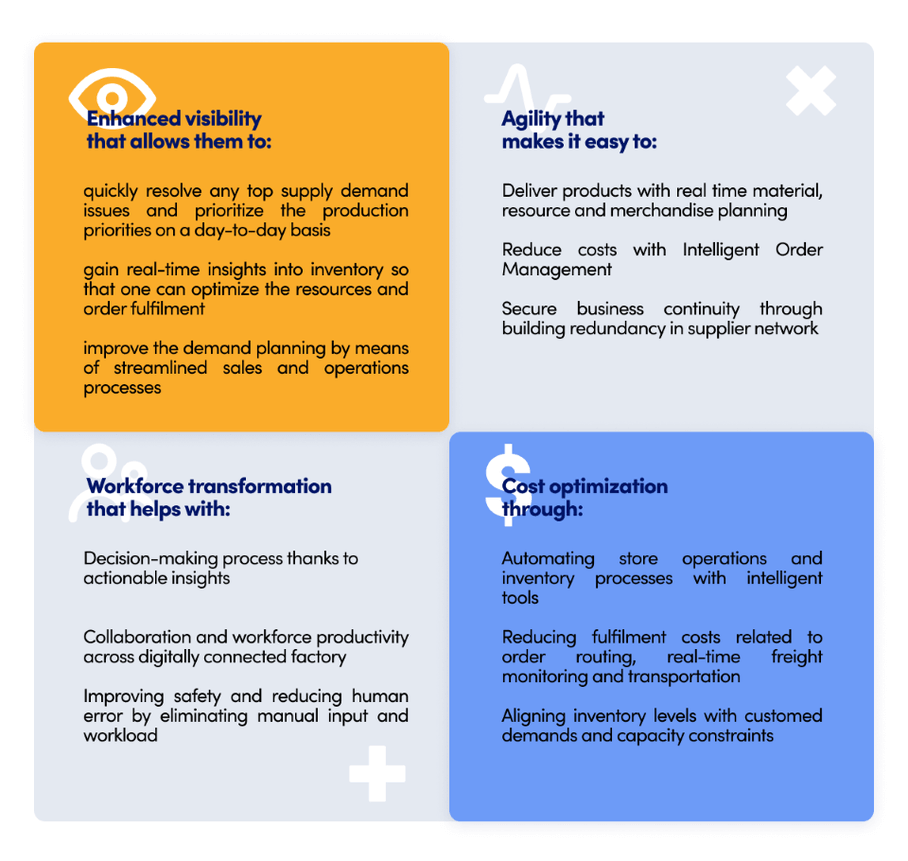

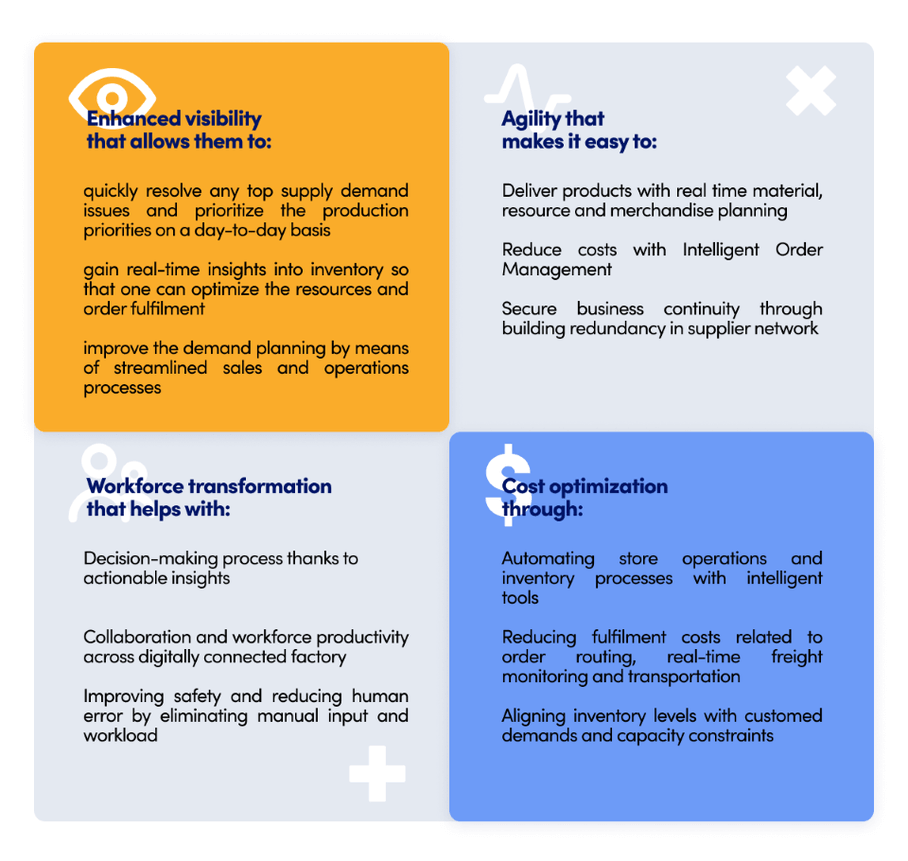

MS Dynamics 365 Supply Chain Management – what manufacturers gain

- Enhanced visibility that allows them to:

- quickly resolve any top supply demand issues and prioritize the production priorities on a day-to-day basis

- gain real-time insights into inventory so that one can optimize the resources and order fulfilment

- improve the demand planning by means of streamlined sales and operations processes

- Agility that makes it easy to:

- Deliver products with real time material, resource and merchandise planning

- Reduce costs with the Intelligent Order Management

- Secure business continuity through building redundancy in the supplier network

- Workforce transformation that helps with:

- Decision-making process thanks to actionable insights

- Collaboration and workforce productivity across digitally connected factory

- Improving safety and reducing human error by eliminating manual input and workload

- Cost optimization through:

- Automating store operations and inventory processes with intelligent tools

- Reducing fulfilment costs related to order routing, real-time freight monitoring and transportation

- Aligning the inventory levels with customer demands and capacity constraints

Make the change – move to MS Dynamics 365 SCM

An intelligent and resilient supply chain is a must in the new industry 4.0. era. And the facts speak for themselves. Companies who have implemented Dynamics 365 Supply Chain and Management see a 20-40% increase in productivity, reduced inventory requirements by 30% and as much as 45% overall operating cost reduction (data from Microsoft, 2022).

Don’t wait – make the move to MS Dynamics 365 SCM and enjoy the benefits of increased agility, visibility, efficiency and productivity.

If you are interested in the topic of manufacturing industries and their challenges, check out our ebook

Dynamics 365 for Manufacturing industry

Also, read more at our website:

Microsoft Dynamics 365 FSCM Implementation